Do You Have A Construction Project We Can Help With?

Valve Installation Procedure

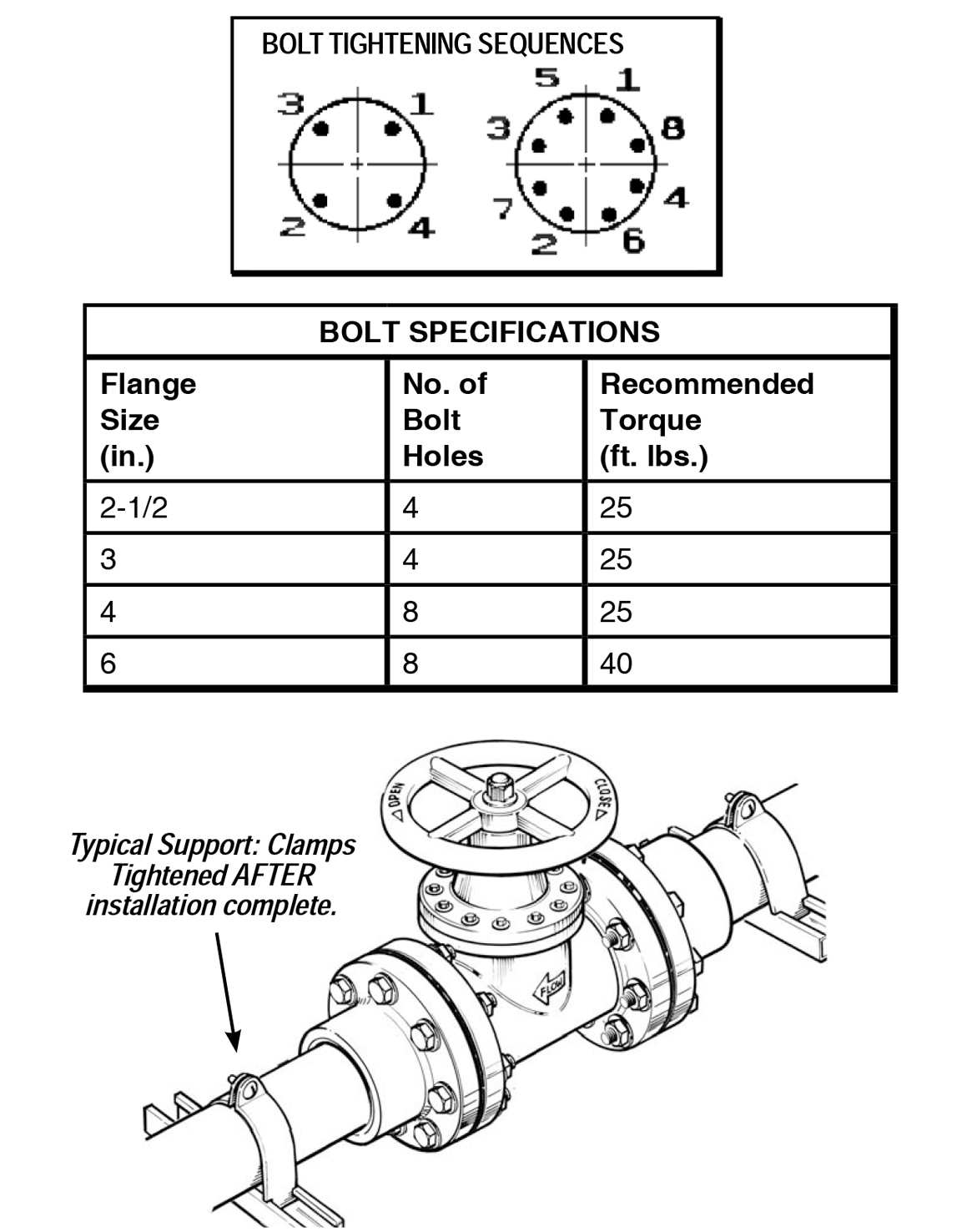

Bolt Preparation For Assembly

Once a flange is attached to the pipe, the method of joining two flanges is as follows:

Suitability of the intended service application should be determined before installation. Plastic piping systems should be engineered, installed, operated & maintained in accordance with accepted standards and procedures for plastic piping systems.

CAUTION: The system must be designed and installed so as not to pull the components in any direction. Pipe system must be cut and isntalled in such a manner as to avoid all stress loads associated with bending, pulling, or shifting. All piping systems must be supported.

DO NOT ATTEMPT TO DRAW TOGETHER ANY GAPS

WITHOUT ALLOWING FREE MOVEMENT TO ONE SIDE OF THE SYSTEM CONNECTION. ADJUST VALVE POSITION AS NECESSARY.

LUBRICATION WARNING: Some Lubricants, including vegetable oils, are known to cause stress cracking in thermoplastic materials. Formulation changes by lubricant manufacturers may alter compatibility of previously accptable materials and are beyond our control.

NOT FOR USE WITH COMPRESSED AIR OR GAS

WARNING: Do not use compressed air or gas to test any PVC or CPVC thermoplastic piping product or system, and do not use devices propelled by compressed air or gas to clear the systems. These practices may result in explosive fragmentation of system piping and components causing bodily injury or death.

All air must be bled from the system during the initial fluid fill. Pressure testing of the system must not be made until all solvent cement joints have properly cured. Initial pressure testing must be made at approximately 10% of the system hydrostatic pressure rating to identify potential problems prior to testing at higher pressures.

Valve Application

These valves may be based on water, both in the context of new and renovating work, buried or installed underground the use of valves allows, to balance the distribution of water in all respects in mesh networks in closing or opening. Maintenance of valves, such as closing and opening, post fire control devices, etc. In the insulation system, perform maintenance operations on the network isolation, removal of an adjacent section of the pipe, in case of failure or incident on a line, the closure will limit the risk of flooding.

Applications of these valve are sewage, water, industrial, and food & beverage systems